The sample is mounted and submerged inside the acrylic box

Dynamic hydrogel grips translate rotational motion into uniaxial strain

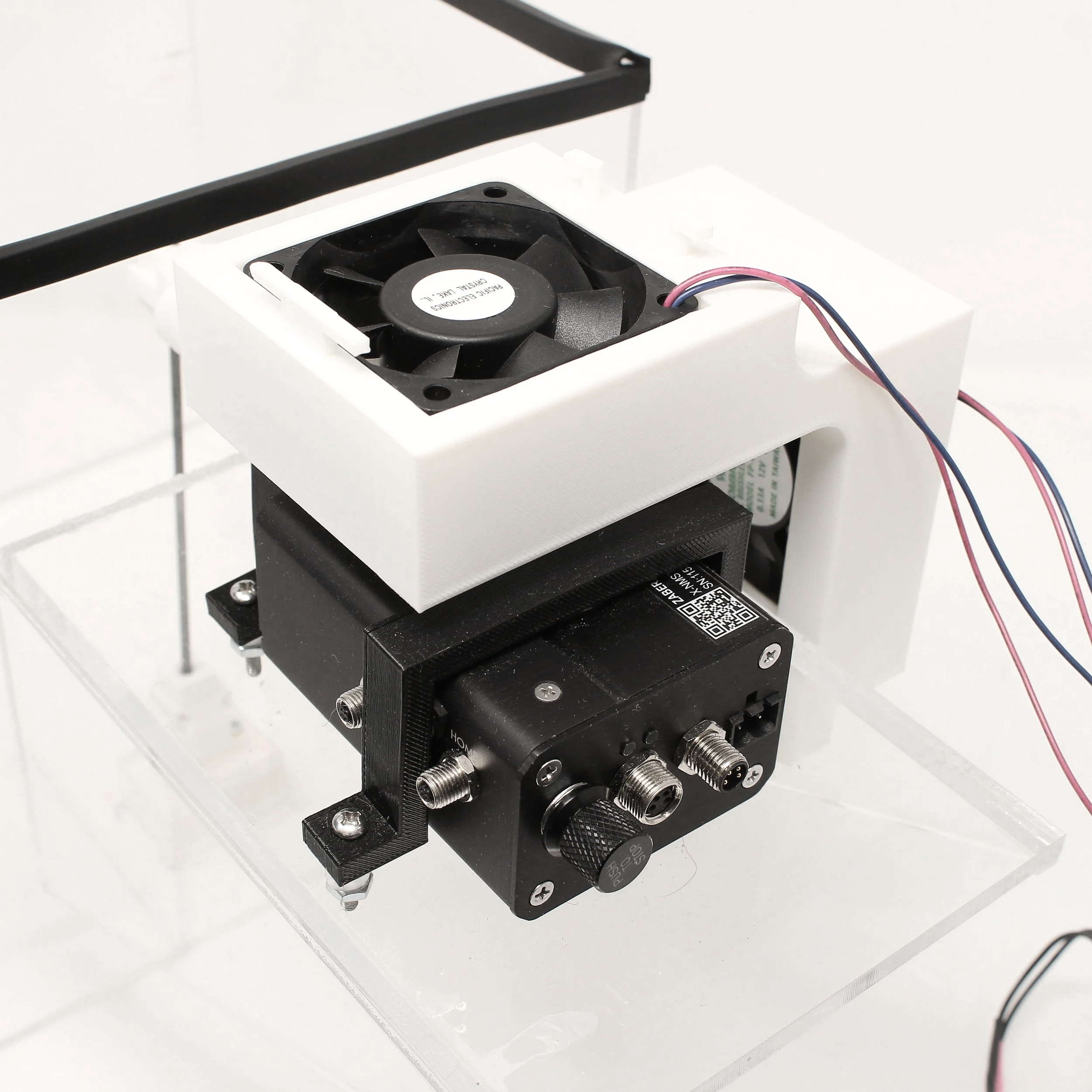

Custom active cooling system

High cycle fatigue testing device

A custom-built chamber for subjecting conductive hydrogels to millions of strain cycles under controlled, physiological conditions. It combines motion control, temperature regulation, sample submersion, and long-duration reliability testing in a compact, low-cost (< $2,500) platform.

Purpose

Evaluate the fatigue performance of soft, conductive hydrogels.

Replicate physiological loading conditions while submerged.

Provide accurate cycle counting for extended-duration tests up to 8 million cycles.

Mechanical Design

Actuation — Zaber stepper motor with integrated encoder driving a custom rotating offset shaft, converting rotational motion to uniaxial strain.

Cycle Capability — Capable of delivering millions of load cycles with adjustable amplitude and frequency.

Enclosure — Custom acrylic test chamber for fluid containment and visibility.

Cooling — Active cooling system prevents motor overheating during extended runs.

Environmental Control

Temperature Regulation — VWR thermocirculator maintains physiological fluid temperature throughout testing.

Submersion — Samples remain fully submersed for realistic conditions.

Control & Data Acquisition

LabVIEW — The user controls the test via an intuitive LabVIEW GUI .

Encoder Feedback — Integrated motor encoder tracks cycle count with high accuracy.

Adjustable Parameters — Rotation speed, offset distance (strain), and fluid temperature can be tuned for different test protocols.

Key Benefits

Enables accelerated life testing of soft materials under realistic conditions.

Long-term operation with stable temperature and active motor cooling.

Compact, modular, and low-cost compared to commercial fatigue testers.